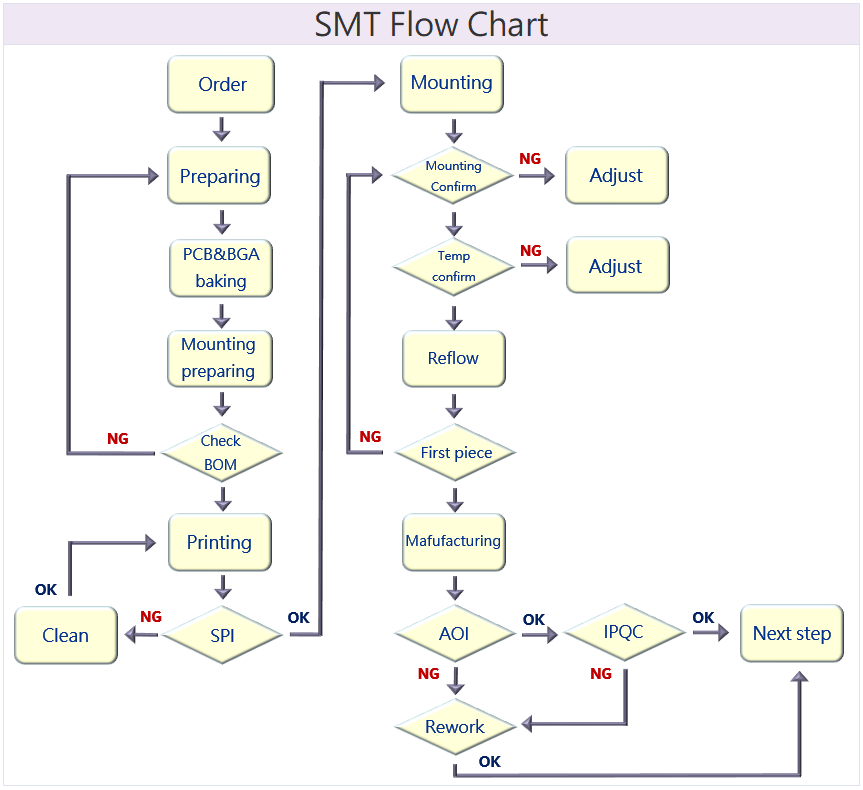

SMT equipment process

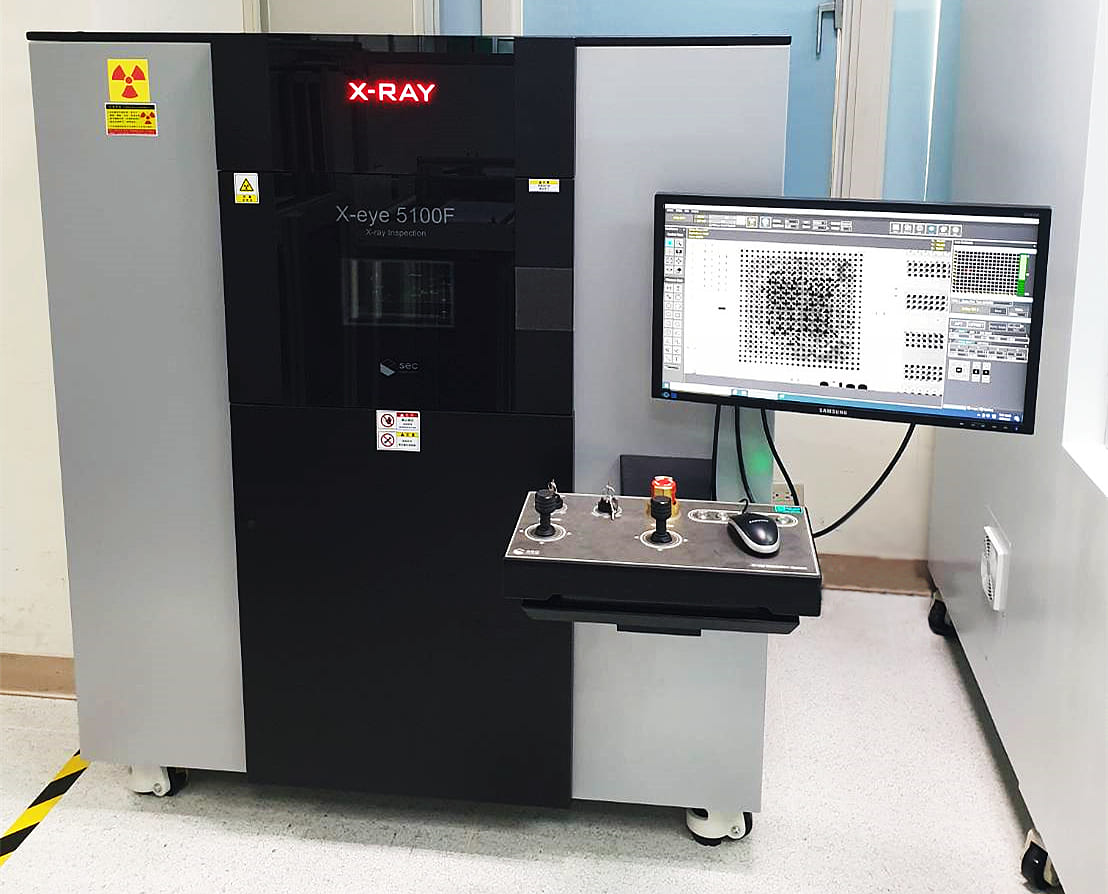

Three SMT lines to manage from sample production to mass production and diversify production models. Besides, we build the smart warehouse system and feeder checking system to confirm the accuracy for the mounting. Each line equipped with auto printer to upgrade the yield. With the AOI inspection to enhance the quality. All the manufacturing area are ESD protected.

|

Item |

Ability |

|

PCB Size |

50mm*50mm-460mm*510mm |

|

Component Size |

Chip 01005(0402mm)-Long CN 100mm |

|

Component pitch |

IC,QFP 0.2mm and |

|

BGA is 0.25mm |

|

|

SMT accuracy |

Chip 0.025mm ; IC 0.015mm |

|

Auto printer Accuracy |

+/-0.025mm |

|

SMT machines |

||||

|

Line |

Brand |

Model |

Accuracy |

CPH |

|

A |

YAMAHA/YAMAHA/JUKI |

Σ-G5S/Σ-G5S/RS1 |

Chip +/- 0.025mm |

192,000 Chips |

|

B |

YAMAHA/YAMAHA/ |

YSM-10/YSM-10 |

Chip +/- 0.025mm |

92,000 Chips |

|

C |

YAMAHA/YAMAHA/ |

YSM-10/YSM-10 |

Chip +/- 0.025mm |

92,000 Chips |

|

Line |

SMT line configuration |

|

A |

Auto printer→SPI→CCD magnifier→High speed mounting→High speed mounting→multi-function mounting→Reflow→3D AOI |

|

B |

Auto printer→SPI→CCD magnifier→Mid high speed mounting→Mid high speed mounting →Reflow |

|

C |

Auto printer→SPI→CCD magnifier→Mid high speed mounting→Mid high speed mounting →Reflow |

CONTACT

CONTACT

RECRUIT

RECRUIT

.png)

.png)